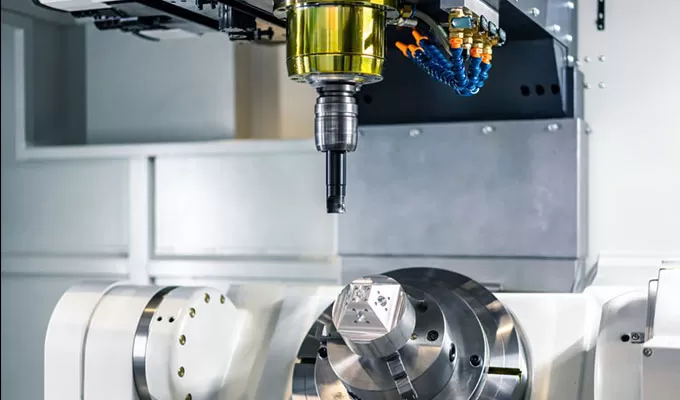

In modern manufacturing, surface treatment and coating are critical processes used to improve the performance, appearance, and longevity of components. These techniques are widely applied in industries such as aerospace, automotive, medical devices, and consumer electronics. This article explores what surface treatment and coating are, their types, functions, and benefits.

What Is Surface Treatment and Coating?

Surface treatment and coating refer to a series of processes applied to the surface of a material—typically metal or plastic—to alter its physical, chemical, or aesthetic properties. The goal is to enhance corrosion resistance, wear resistance, electrical conductivity, or adhesion while also improving the product’s appearance.

These treatments can be chemical (like anodizing or passivation), mechanical (such as polishing or blasting), or involve adding a coating layer (like powder coating or electroplating).

Types of Surface Treatments and Coatings

There are various surface treatment and coating techniques, each tailored to specific material properties or application requirements. Here's a simplified table highlighting some common methods:

| Treatment Type | Method | Main Purpose |

|---|---|---|

| Chemical Treatment | Anodizing, Passivation | Corrosion resistance |

| Mechanical Treatment | Sandblasting, Polishing | Surface preparation & aesthetics |

| Coating Techniques | Powder Coating, PVD | Wear resistance, appearance |

| Electrochemical Coating | Electroplating | Conductivity, protection |

Benefits of Surface Treatment and Coating

Applying surface treatment and coating offers numerous advantages:

Extended lifespan: Treated parts are less prone to corrosion and wear.

Improved performance: Reduced friction, better conductivity, or enhanced bonding surfaces.

Enhanced aesthetics: Uniform finishes and a wide range of colors or textures.

Environmental protection: Certain coatings offer protection in harsh environments.

These benefits help improve the reliability and performance of components across demanding applications.

Applications Across Industries

Surface treatment and coating are essential in precision manufacturing and product development:

Aerospace: for lightweight parts that resist oxidation.

Medical: for biocompatible implants with strong wear resistance.

Automotive: for improved durability and visual appeal.

Electronics: for protecting circuit boards and connectors from moisture or heat.

The choice of treatment depends on factors such as material type, intended use, environmental exposure, and required longevity.

By using advanced surface treatment and coating techniques, manufacturers can significantly improve both the performance and appearance of their products. These processes are a cornerstone of high-precision industries. For reliable, high-quality surface finishing solutions, ANOK offers comprehensive services tailored to meet the needs of modern manufacturing.

EN

EN