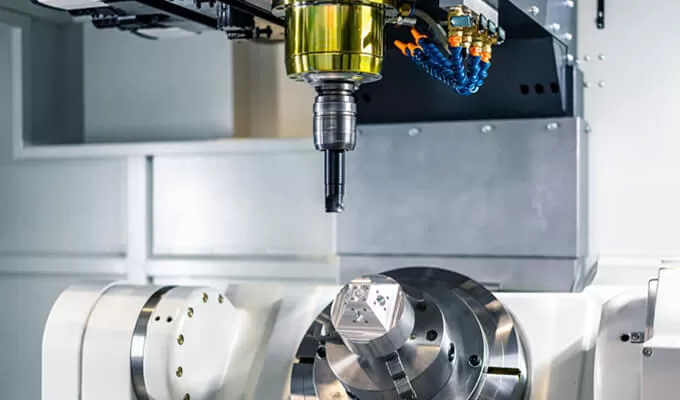

ANOK is a leading provider of industrial CNC machining solutions, delivering high-precision, reliable, and cost-effective services to meet the demands of industries worldwide. Whether it's small-scale production or large-volume runs, ANOK's advanced CNC machining capabilities can handle a variety of materials and complex designs. Here's an overview of the key advantages and features of industrial CNC machining at ANOK.

One of the primary advantages of industrial CNC machining is its ability to work with a diverse array of materials. From metals to plastics, ANOK's CNC machines can process everything from lightweight aluminum to hard-to-machine titanium and high-performance polymers. The ability to handle such varied materials makes ANOK a go-to choice for industries including aerospace, automotive, and electronics.

| Material Type | Common Applications | CNC Machining Capability |

|---|---|---|

| Aluminum Alloys | Aerospace, Automotive | Milling, Turning |

| Stainless Steel | Medical Devices, Machinery | Precision Milling |

| Titanium | Aerospace, Defense | 5-Axis CNC Machining |

| PEEK, POM | Electronics, Medical | CNC Turning, Milling |

Industrial CNC machining is known for its high-precision capabilities, ensuring that each part meets the exacting specifications required by industries where accuracy is paramount. With tolerances as tight as ±0.002 mm, ANOK can create intricate components with complex geometries that other methods cannot achieve. Whether it’s a one-off prototype or a production run, CNC machines consistently deliver high-quality results.

ANOK leverages cutting-edge CNC machining technology to offer fully customized solutions for its clients. From multi-axis CNC machines to advanced CAD/CAM systems, ANOK’s machines are equipped with the latest features to handle even the most complicated designs. With industrial CNC machining, the company provides flexibility in creating custom tools, specialized fixtures, and unique parts that are optimized for performance and efficiency.

One of the key benefits of industrial CNC machining is the ability to balance high precision with cost-effective production. ANOK’s CNC machines are designed for both low-volume and high-volume manufacturing, offering quick turnaround times while minimizing material waste and reducing labor costs. This makes ANOK a competitive choice for businesses seeking reliable, cost-effective manufacturing solutions.

In summary, ANOK's industrial CNC machining services are designed to meet the evolving needs of industries requiring precision, efficiency, and versatility. By offering high-quality machining across a wide range of materials and complex geometries, ANOK remains a trusted partner for companies looking for reliable, customized, and cost-effective solutions. Reach out to ANOK today for your next industrial CNC machining project and experience the difference.