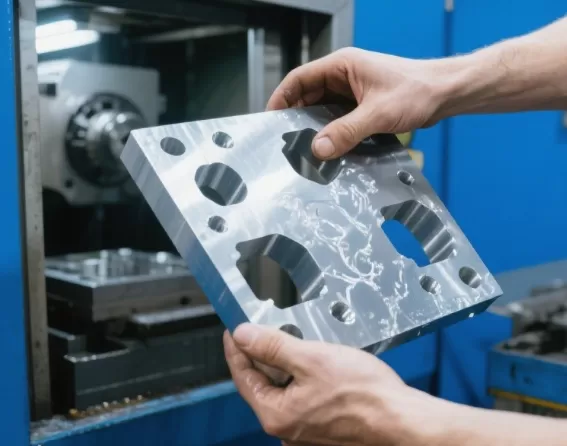

In the competitive world of CNC machining, reducing maintenance costs is a top priority for businesses. One effective way to achieve this is through advanced surface treatment (Surface Treatment) techniques. By selecting the right surface treatment, companies can significantly extend the lifespan of their CNC components, thereby reducing the frequency and cost of maintenance.

To lower maintenance costs, it is essential to choose a surface treatment that enhances the durability and performance of CNC parts. Techniques such as anodizing, electroplating, and sandblasting can minimize wear and tear, reduce corrosion, and improve surface smoothness. These benefits collectively contribute to lower maintenance requirements and costs.

In this article, we will delve into the various surface treatment options available, their specific benefits, and how they can be optimized to reduce maintenance costs for CNC machined parts. By understanding these factors, businesses can make informed decisions that lead to long-term savings and improved operational efficiency.

Choosing the right surface treatment process is crucial because it directly impacts the longevity of CNC components. There are several reasons for this. Firstly, a suitable surface treatment can significantly enhance the wear resistance of the parts, thereby reducing the rate of deterioration. Secondly, it can provide a protective layer that shields the components from environmental factors such as moisture and chemicals, which can cause corrosion. Additionally, the right surface treatment can improve the mechanical properties of the parts, such as hardness and tensile strength, making them more robust and durable. Moreover, by reducing the surface roughness, the treatment can minimize friction and wear during operation. Consequently, there is a direct correlation between the choice of surface treatment and the lifespan of CNC components. Therefore, businesses must carefully evaluate their options to ensure they select the most appropriate treatment for their specific needs.

| Surface Treatment | Benefits | Applications |

|---|---|---|

| Anodizing treatment | Enhances corrosion resistance, improves surface hardness | Aerospace, automotive |

| Electroplating | Provides a protective coating, reduces friction | Electronics, machinery |

| Sandblasting | Cleans and smooths surfaces, prepares for further treatment | Construction, manufacturing |

Anodizing, electroplating, and sandblasting are three surface treatment techniques that can significantly reduce mechanical wear. Anodizing, for instance, enhances the corrosion resistance and surface hardness of aluminum parts, making them ideal for aerospace and automotive applications. Electroplating, on the other hand, provides a protective coating that reduces friction and wear, commonly used in electronics and machinery. Sandblasting cleans and smooths surfaces, preparing them for further treatment and reducing the likelihood of mechanical wear. By understanding the specific benefits of each technique, businesses can select the most suitable surface treatment to minimize wear and extend the lifespan of their CNC components.

Optimizing surface treatment processes is essential for reducing corrosion in metal components. There are several strategies to achieve this. Firstly, selecting the right surface treatment, such as anodizing or electroplating, can provide a protective barrier against corrosive elements. Secondly, ensuring proper application techniques, such as maintaining the correct temperature and pH levels during treatment, can enhance the effectiveness of the protective layer. Additionally, regular maintenance and inspection of treated components can help identify and address any early signs of corrosion. Furthermore, using high-quality materials and chemicals in the treatment process can improve the overall durability of the protective layer. By implementing these strategies, businesses can significantly reduce the risk of corrosion and extend the lifespan of their metal components.

Improving the surface roughness of CNC machined parts through surface treatment can significantly reduce frictional resistance. For example, in the aerospace industry, where CNC aerospace parts are subject to high levels of stress and friction, surface treatments like anodizing and electroplating can create a smoother, more uniform surface. This not only reduces friction but also enhances the overall performance and efficiency of the parts. Additionally, techniques such as sandblasting can remove surface imperfections and prepare the parts for further treatment, resulting in a smoother finish. By reducing surface roughness, businesses can minimize wear and tear, improve the efficiency of their CNC components, and ultimately reduce maintenance costs.

In high-load environments, selecting the right surface treatment is crucial for extending the maintenance cycle of components. Techniques such as hard anodizing and thermal spraying are particularly effective in these conditions. Hard anodizing creates a thick, durable oxide layer that enhances the wear resistance and corrosion protection of the parts. Thermal spraying, on the other hand, involves applying a coating of molten material to the surface, creating a robust protective layer. These treatments can withstand high levels of stress and wear, making them ideal for heavy-duty applications. By choosing the appropriate surface treatment, businesses can significantly extend the maintenance cycle of their components, reducing downtime and maintenance costs.

Testing and validation are essential for verifying the effectiveness of surface treatment processes in reducing maintenance costs. There are several methods to achieve this. Firstly, conducting accelerated wear and corrosion tests can provide valuable data on the durability and performance of treated components. Secondly, implementing a monitoring system to track the performance of treated parts in real-world conditions can help identify any issues early on. Additionally, comparing the maintenance costs and downtime of treated versus untreated components can provide a clear indication of the benefits of the surface treatment. By using these testing and validation methods, businesses can ensure that their chosen surface treatment processes are effectively reducing maintenance costs and improving the overall performance of their CNC components.