In the competitive landscape of modern manufacturing, speed and precision are critical. For B2B clients, the ability to quickly move from design to prototype can make the difference between success and missed opportunities. CNC precision machining has emerged as a game-changer in rapid prototyping, offering unparalleled speed, accuracy, and versatility. This article explores the myriad advantages of CNC precision machining, demonstrating why it is the preferred choice for businesses aiming to stay ahead of the curve.

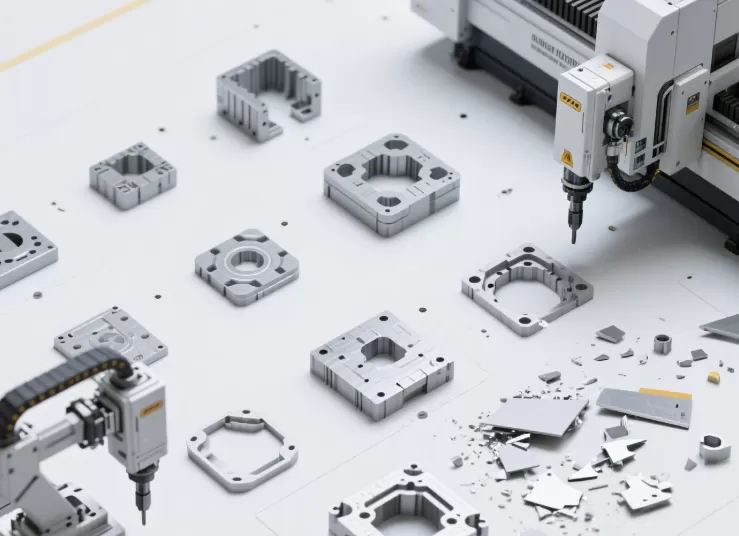

CNC precision machining stands out as the fastest route from design to prototype due to its automated nature and high-speed capabilities. By utilizing computer-aided design (CAD) files, CNC machines can quickly interpret and execute complex geometries with minimal human intervention. This automation reduces the risk of errors and accelerates the production process. Additionally, CNC machines can operate continuously, 24/7, further shortening lead times. The ability to rapidly switch between different designs without extensive retooling also contributes to its speed, making CNC precision machining an ideal solution for businesses that need to iterate quickly and efficiently.

Traditional manufacturing methods often involve multiple steps, each requiring manual setup and adjustment, which can significantly extend lead times. In contrast, CNC machining streamlines the entire process by integrating design, programming, and production into a seamless workflow. The use of advanced software allows for precise control over every aspect of the machining process, from tool paths to cutting speeds. This level of control not only enhances efficiency but also ensures consistent quality. Moreover, CNC machines can handle complex designs that would be time-consuming or impossible to achieve with traditional methods, further reducing the time from concept to prototype.

The accuracy of CNC precision machining is unmatched, thanks to its ability to execute intricate designs with micron-level precision. This high degree of accuracy is achieved through the use of advanced control systems and feedback mechanisms that continuously monitor and adjust the machining process. The result is a flawless prototype that closely matches the original design specifications. Additionally, Metal CNC Machine can produce consistent results across multiple iterations, ensuring that each prototype meets the same high standards. This level of precision is particularly important for industries where even the smallest deviation can impact the functionality and performance of the final product.

One of the standout features of CNC precision machining is its versatility in handling a wide range of materials. Whether it’s metals like aluminum and steel, plastics such as ABS and polycarbonate, or exotic alloys like titanium and Inconel, CNC machines can process them all with ease. This material freedom allows businesses to choose the best material for their specific application, without being constrained by the limitations of the manufacturing process. The ability to work with diverse materials also opens up new possibilities for innovation, enabling the creation of prototypes that are not only functional but also optimized for performance and durability.

CNC precision machining offers a cost-effective solution for prototyping, despite its advanced capabilities. The initial investment in CNC equipment is offset by the savings in labor costs and the reduction in material waste. CNC machines can produce parts with minimal material wastage, thanks to their precise cutting and shaping abilities. Additionally, the automation of the machining process reduces the need for skilled labor, further lowering costs. The ability to quickly produce prototypes also means that businesses can bring products to market faster, generating revenue sooner and improving overall profitability.

| Aspect | CNC Precision Machining | Traditional Methods |

|---|---|---|

| Speed | High-speed, automated production | Slower, manual setup and adjustment |

| Accuracy | Micron-level precision | Lower precision, more variability |

| Material Versatility | Handles metals, plastics, exotic alloys | Limited material options |

| Cost | Lower labor costs, minimal waste | Higher labor costs, more material waste |

| Consistency | Consistent quality across iterations | Variability between iterations |

CNC precision machining is not only ideal for rapid prototyping but also facilitates a seamless transition to mass production. Once a prototype is finalized, the same CNC programs can be used to produce large quantities of the part with consistent quality. This eliminates the need for retooling and reduces the risk of errors during scale-up. The ability to quickly switch between different production runs also allows for greater flexibility in manufacturing, enabling businesses to respond to changing market demands. By leveraging CNC precision machining, companies can streamline their production processes, reduce lead times, and maintain high standards of quality from prototype to final product.