As a high-performance material, carbon fiber has shown extremely wide and critical application value in many important industries such as military, medical, outdoor and industrial with its excellent properties such as high strength, low density, corrosion resistance and fatigue resistance. These composite parts are particularly popular in aerospace, shipbuilding and sporting goods. Among the different processes, carbon fiber processing is one of the famous tools used to make parts of various shapes and sizes. Carbon fiber materials can be processed by mechanical processing methods such as milling, turning, drilling, and tapping. However, due to its hardness, brittleness and abrasiveness, it is difficult to process. The processing of carbon fiber parts requires consideration of too many materials, geometries, cutting parameters and other factors.

In this article, we will explore what is carbon fiber, its properties, processing operations, and its characteristics and application advantages in different industries.

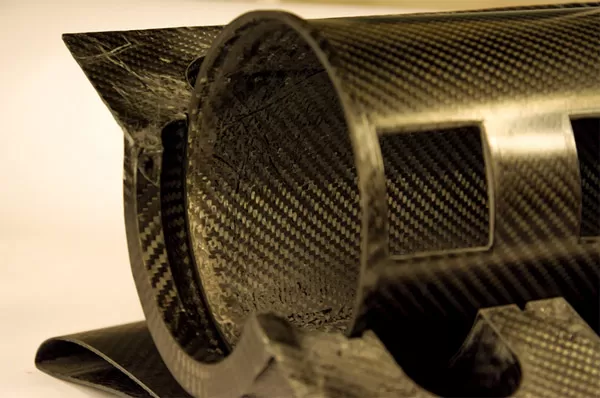

What is a Carbon Fiber Composite?

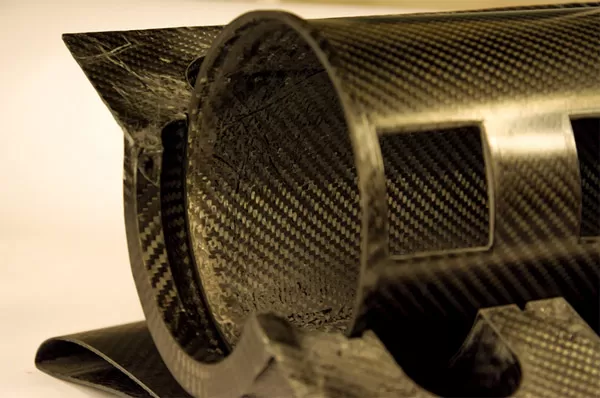

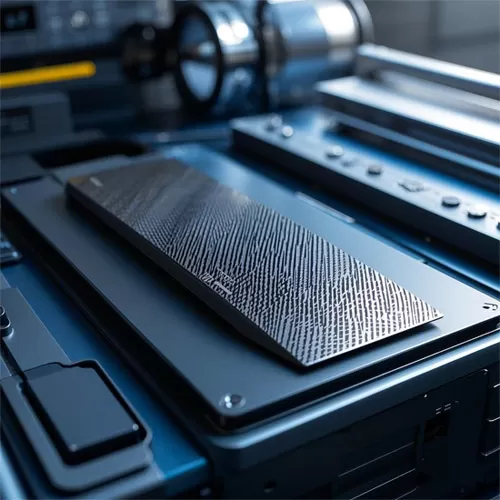

Carbon fiber raw material

Carbon fiber composites are made of long, tightly interlocked carbon fiber chains bound together with a resin to form a matrix. The fibers are typically up to 10 microns in diameter and weigh significantly less than other engineering materials such as steel and titanium.

Substances such as polyacrylonitrile (PAN) provide the carbon fibers needed to make composite panels. These fibers are woven into fabrics or laid up, then impregnated with epoxy resin to form a prepreg. Next, the prepreg is molded and cured under heat and pressure to form a composite panel.

What are the Properties of Carbon Fibers?

Rigid carbon fiber materials have excellent strength-to-weight ratio, stiffness, wear resistance, superior corrosion resistance and other beneficial properties. These are critical to the manufacturing industry, especially aerospace and similar high-strength and lightweight applications.

The properties are as below:

High mechanical strength

Minimal thermal expansion to withstand harsh environments.

Strong and lightweight

Excellent damping and self-lubricating properties

High fatigue resistance and durability

Smooth and nice surface

Resistant to corrosion, wear, scratch and abrasion

In addition, carbon fiber is five times stronger than steel at the same weight, which shows that carbon fiber can be used to make lightweight components without sacrificing strength.

Table:carbon fiber properties(From: Research Gate)

Parameter | Value |

Fibre diameter | 5μm |

Tensile modulus | 294 GPa |

Tensile strength | 5880 MPa |

Fibre areal weight | 268 g/m³ |

Density | 1.8 g/cm³ |

Thermal conductivity | 70 W/m.K |

Strain | 2% |

Challenges in Carbon Fiber Processing

The toughness, wear resistance, and dense structure of carbon fiber make it difficult to process with simple tools and parameters, such as in metal processing. Therefore, there are some complexities and challenges in carbon fiber processing. However, recognizing potential problems and taking preventive measures can eliminate processing challenges and defects.

·Carbon fiber has low thermal conductivity

The low thermal conductivity of the material is one of the machining challenges because it generates heat in the machining area and in the cutting tool – a small amount of heat flows through the chip. As a result, it can degrade performance or delaminate the carbon fiber layers.

Prevention: Use specialized coolants, controlled cutting speeds and advanced tool coatings.

· Wear resistance of carbon fiber

Carbon fiber workpieces are abrasive, causing rapid tool wear and equipment vibration. As a result, surface roughness and irregularities will be high.

Prevention: Use diamond-coated tools and stable machining settings to reduce tool wear and vibration.

·Dust from carbon fiber

Carbon fiber processing produces more dust particles than other materials, which not only causes management problems but also endangers human health.

Prevention: Ventilation systems, dust collection systems, PPE and other arrangements are required.

·Inconsistent layer cutting

Carbon fiber composites are often layered with different materials or orientations to enhance specific mechanical properties. These variations affect how each layer responds to machining, resulting in inconsistent cut quality, varying thickness, and weakened structural integrity.

Prevention: Adjust parameters with real-time feedback, toolpath simulation, and tight hold of the composite workpiece.

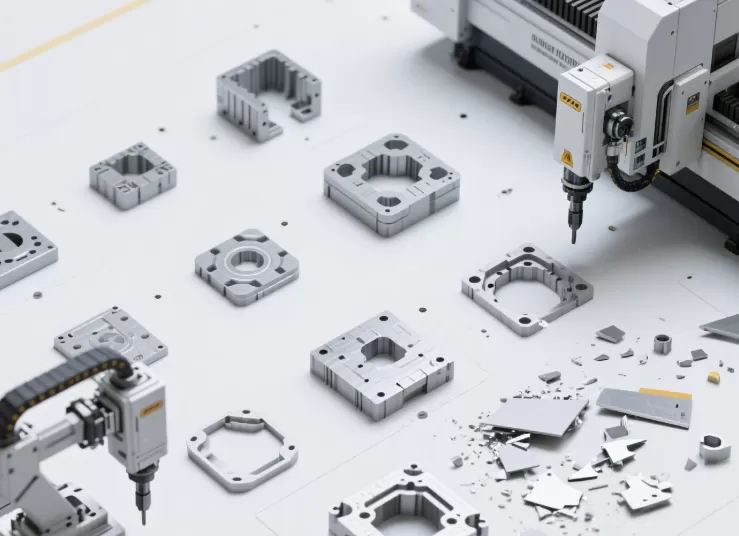

Advantages of CNC Machining Carbon Fiber

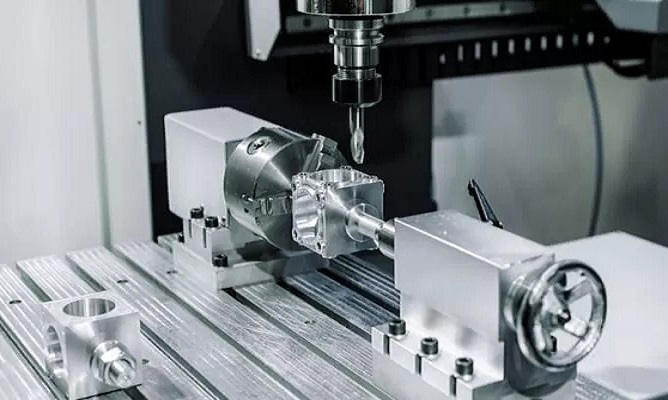

High precision: CNC machining relies on computer program control, which can accurately control the tool's motion trajectory and machining parameters, and can achieve micron-level machining accuracy, meeting the strict requirements of carbon fiber parts for dimensional accuracy and shape accuracy. It is especially suitable for fields with extremely high precision requirements such as aerospace, electronics, etc.

High repeatability: Once the processing program is written, the CNC machine tool can repeatedly process multiple identical carbon fiber parts according to the same program, ensuring the consistency and stability of part quality, which is suitable for mass production.

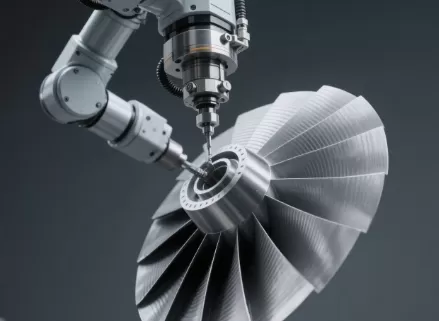

Complicated shapes can be processed: CNC machine tools have multi-axis linkage functions, which can realize complex curve and surface processing in three-dimensional space. This enables it to process various complex carbon fiber products, such as aircraft engine blades, special-shaped automotive parts, etc.

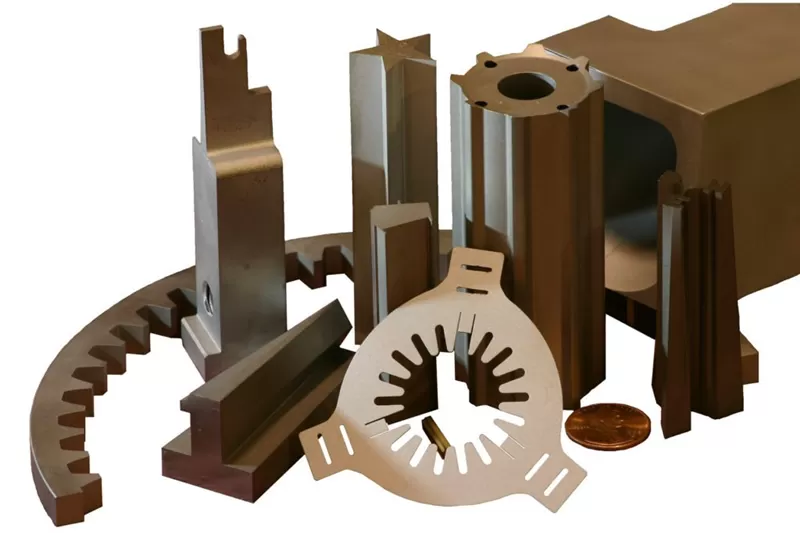

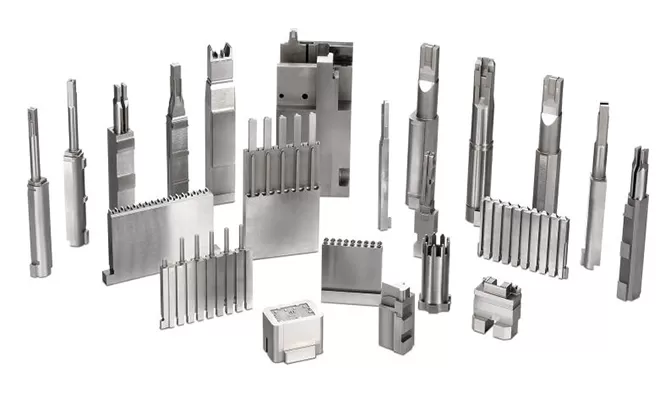

Carbon Fiber Processing Technology

Carbon fiber can be processed into the desired shape through various machining processes, including milling, turning, drilling, etc. Each process uses different machining tools and provides unique capabilities.

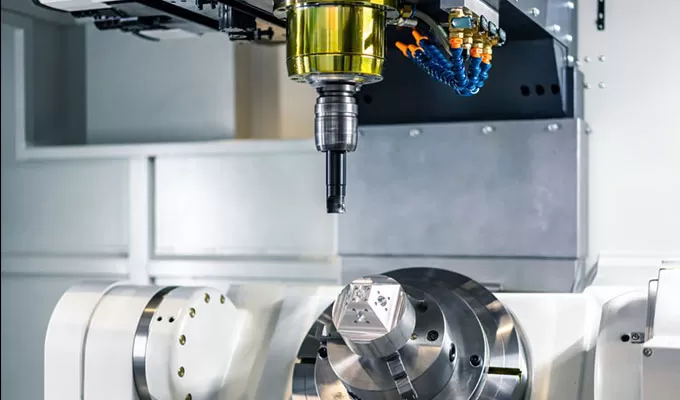

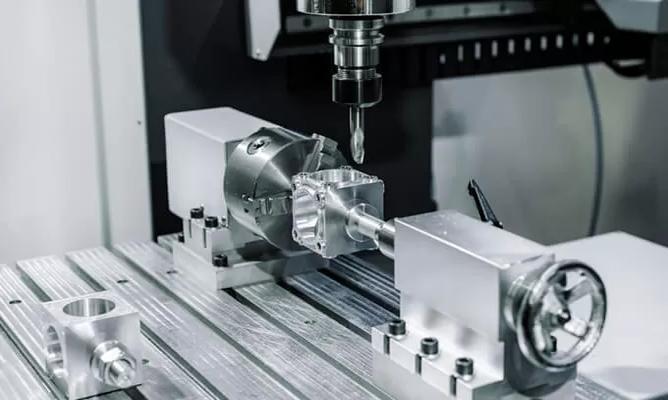

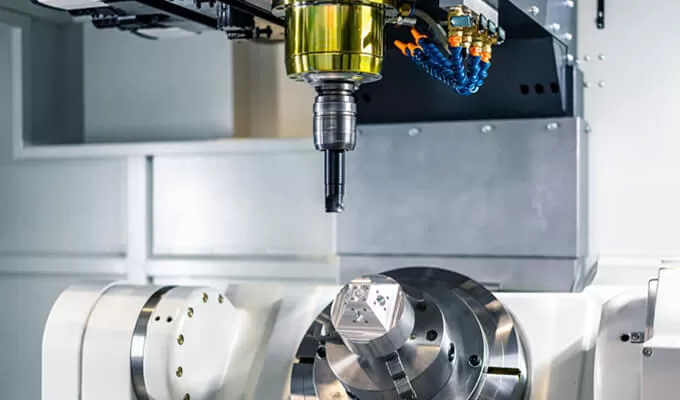

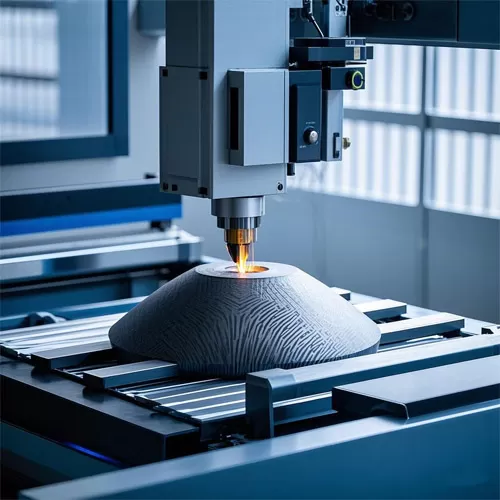

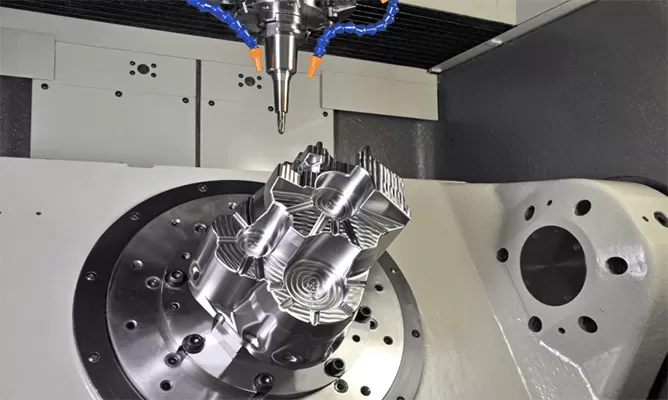

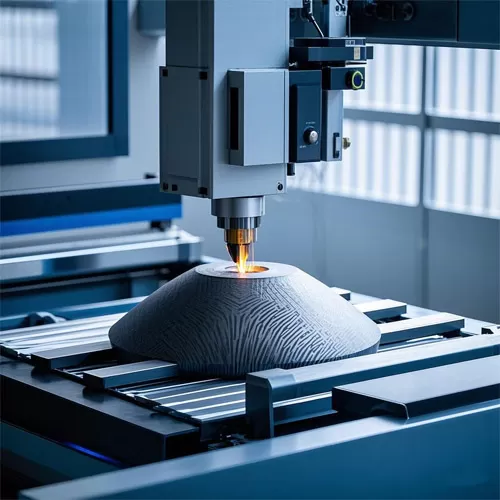

1. CNC Milling

The milling process uses a rotating cutting tool to remove material and create complex shapes with precise dimensions. The preferred tool for this process is a diamond-coated or polycrystalline diamond (PCD) end mill. They are highly resistant to the abrasive nature of carbon fiber. For carbon fiber milling, a spindle speed of 5,000-7,000 RPM and a feed rate of 0.02-0.05 mm/rev are optimal.

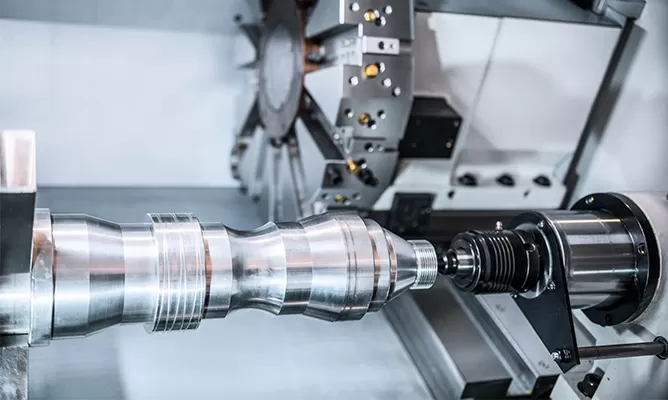

2. Turning

During turning, the workpiece rotates while a fixed cutting tool removes material by feeding into the workpiece. It is mainly used to manufacture cylindrical carbon fiber components. Meanwhile, diamond-coated or PCD lathe tools are ideal for turning. Subsequently, moderate spindle speeds and controlled feed rates are required to prevent delamination of the carbon fiber layers.

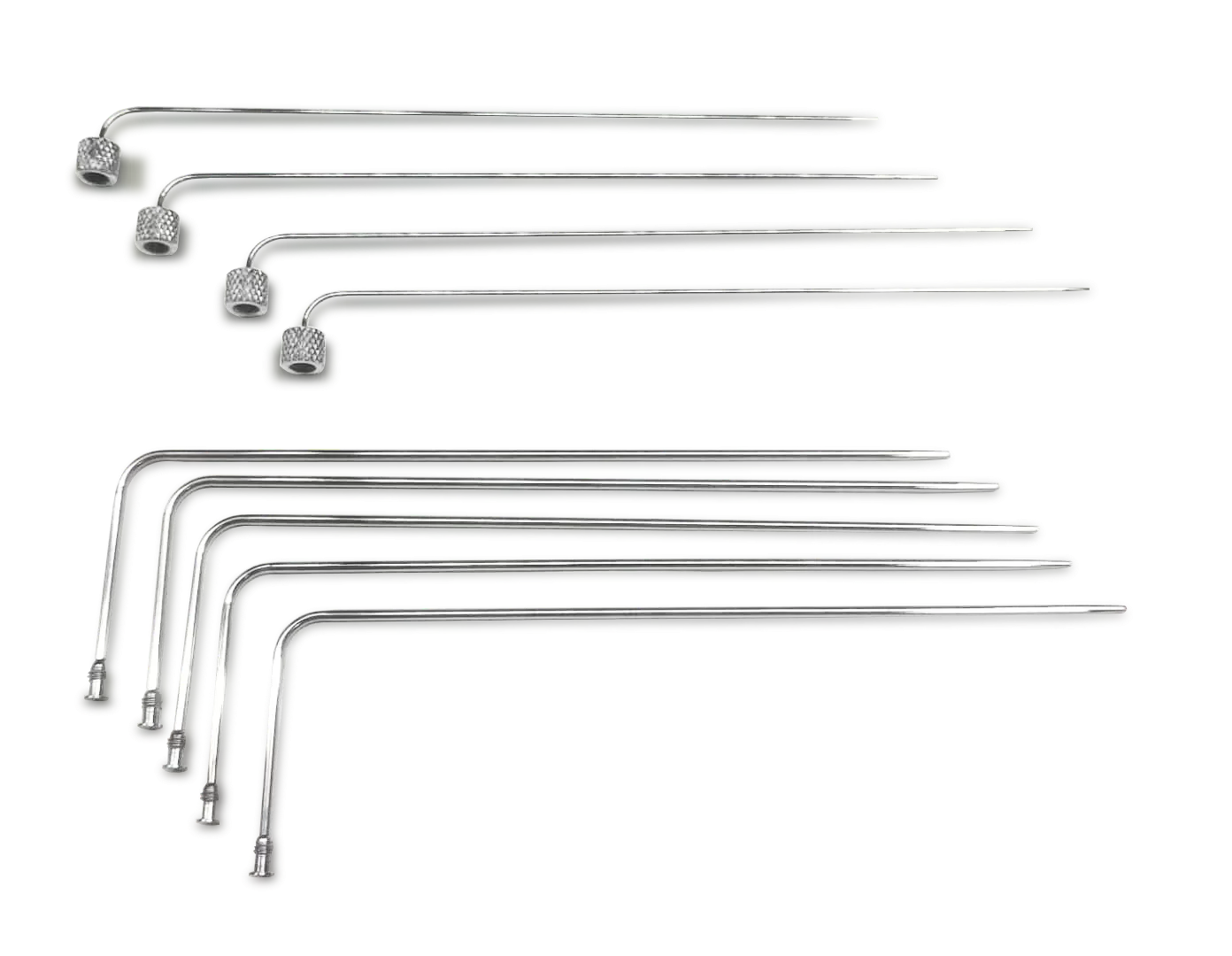

3. Drilling

The drill rotates inward from the workpiece surface, removing material to create a hole the same diameter as the drill. Carbon fiber drilling is particularly challenging because the material is susceptible to wear and delamination. It is best to use a specialized drill with a negative rake angle and high spindle speed to minimize these problems.

4. Tapping

Tapping forms threads within a drilled hole and is commonly used for fasteners in carbon fiber components. Tapping requires precision and care to avoid damaging the composite structure during carbon fiber machining. Specialized taps designed for composites, often coated with titanium or diamond, can enhance drilling performance.

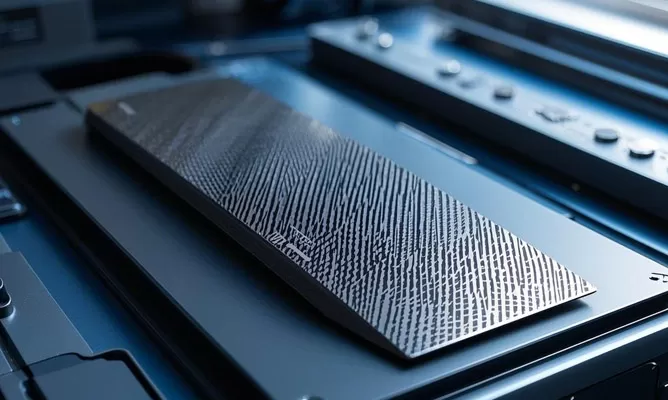

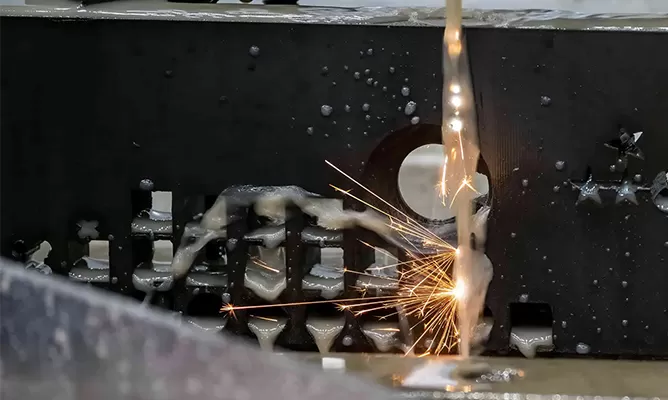

5. Waterjet Cutting

Water jet cutting machines use a high-pressure water jet, often mixed with abrasive particles, to cut materials into designed shapes or patterns. The process is very effective for carbon fiber sheets because it creates minimal thermal stress and avoids delamination. Therefore, water jets can achieve complex shapes and features.

6. Surface Treatment

Laser cutting has the advantages of high precision, high speed, and smooth incision. It can accurately remove tiny burrs and cause less damage to carbon fiber products. It is especially suitable for processing carbon fiber parts with high precision requirements.

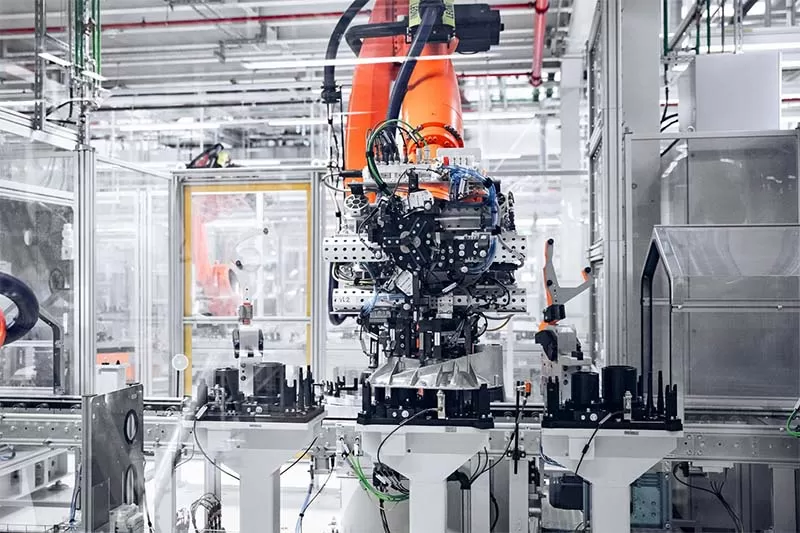

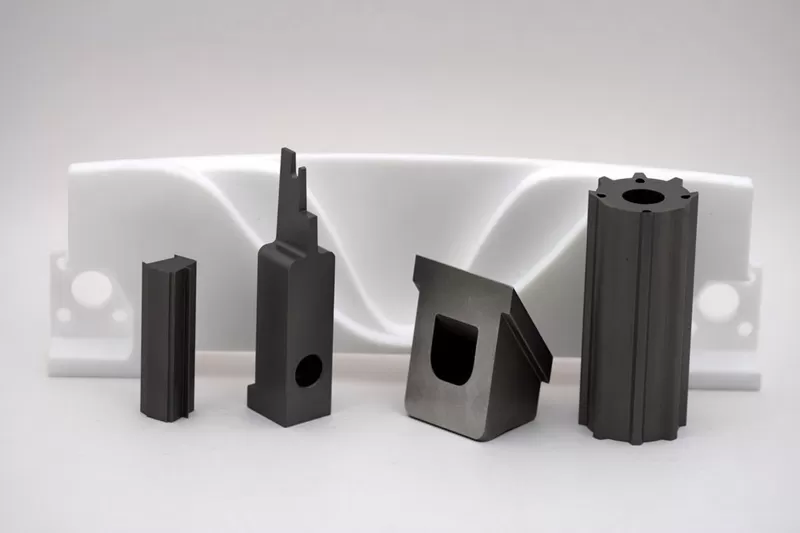

Application of Carbon Fiber CNC Machining

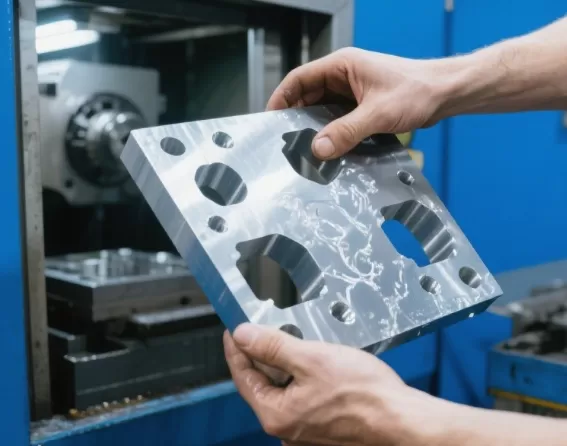

CNC lathes, milling machines, turning centers and all equipment use computer numerical control to perform material removal. Subsequently, they can accommodate different types of tools depending on the machining requirements. These two features and many others of CNC machines make them ideal for processing carbon fiber into functional parts for a variety of industries, such as aerospace, automotive, electronics, and more.

Custom carbon fiber machining parts

Military

In the military industry, carbon fiber composites are shining. Carbon fiber can improve the performance and efficiency of equipment and vehicles, provide excellent ballistic protection and higher fuel efficiency. At the same time, it can maintain the structural integrity of vehicle component systems under extreme conditions. For example:

Body armor

Helmuts

Vehicle armor plates

Missile hulls

Portable shelters

Radar covers

Antenna structures

Carbon Fiber Body Armor and Protective Gear

Medical

Carbon fiber has high corrosion and wear resistance, making it suitable for some medical implants and a variety of medical device components. In addition, it is biocompatible and has an elastic modulus close to that of human bone. For example:

Carbon fiber medical equipment bracket

Outdoors

In the outdoor field, carbon fiber is revolutionizing all kinds of equipment with its unique properties. Carbon fiber is lightweight and can also be used in a variety of sporting goods, such as bicycles and skis. Its light weight and high strength enhance its performance. The carbon hubs can improve drive response, save weight and increase wheel build stiffness. For example:

Carbon fiber knife handles for survival in hostile environments

Carbon fiber tent pole Carbon fiber bicycle sleeve

Carbon hub for bikes

Industrial Engineering

Aerospace

Carbon fiber plays an important role in the aerospace industry, from commercial aircraft to drones, rockets, and satellites. This is primarily due to two reasons: strength and weight. Additionally, CNC machining can handle tight tolerances and complexities. For example:

Carbon fiber UAV frames

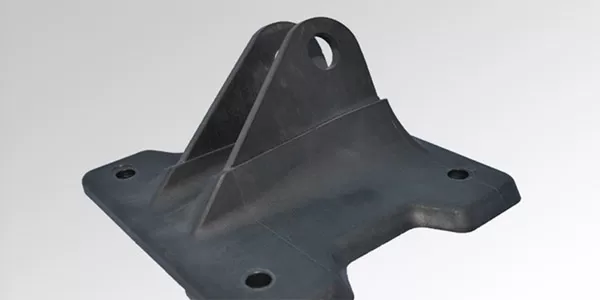

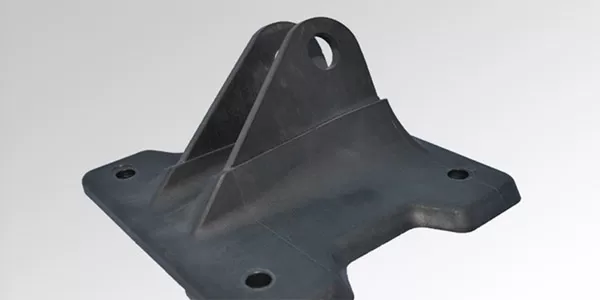

Carbon fiber bracket

Automotive

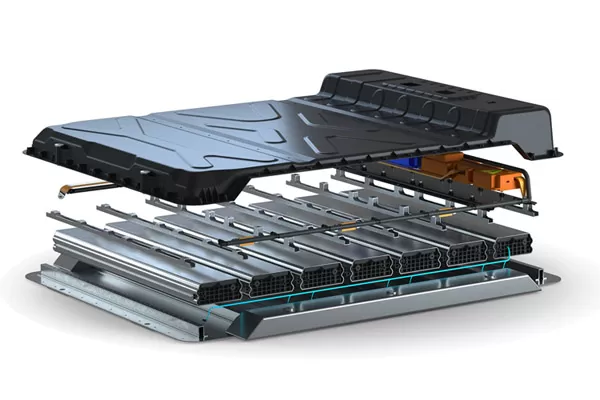

Carbon fiber can be used to make car hoods, doors, roofs and other parts. For example, some high-end sports cars use carbon fiber body parts, which reduces weight while improving the acceleration and braking performance of the vehicle. For new energy vehicles, carbon fiber composite materials can be used to make battery boxes.

Carbon fiber auto parts

Marine

In shipbuilding, carbon fiber can be used to manufacture components such as hulls, masts, and propeller shafts.

Carbon fiber steering wheel

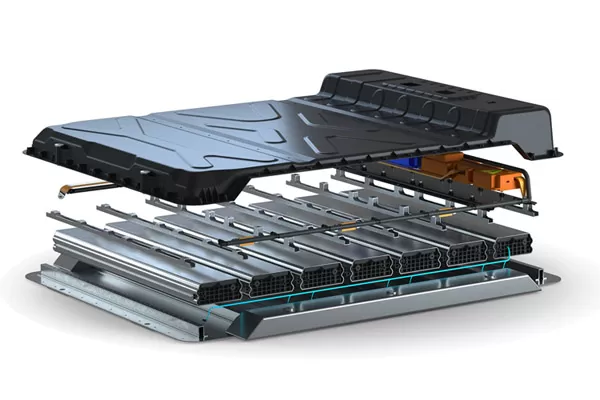

Energy Storage

Carbon fiber is widely used in the manufacture of wind turbine blades. It can also be used to manufacture solar panel frames, oil rig components, battery enclosures, etc.

Carbon fiber battery enclosure

Oil and Gas (Offshore Drilling)

In the oil industry, carbon fiber composites can be used to manufacture oil pipelines. Its corrosion resistance can effectively resist the erosion of corrosive substances in oil and extend the service life of pipelines. At the same time, carbon fiber pipelines are light in weight and easy to install and transport.

Carbon fiber oil pipeline part

Carbon Fiber Machining Capability at ANOK

ANOK Precision provides a full service for your carbon fiber solutions, ranging from engineering, initial design, testing and development through custom volume production. Our in house CNC machining capability allows us to efficiently and cost effectively produce carbon fiber parts for our customers for many years.

·Engineering & Design

ANOK provides a full service program capable of turning your conceptual design into a manufacturing reality. We have the capability to undertake your any projects. Just contact ANOK and tell us your thoughts!

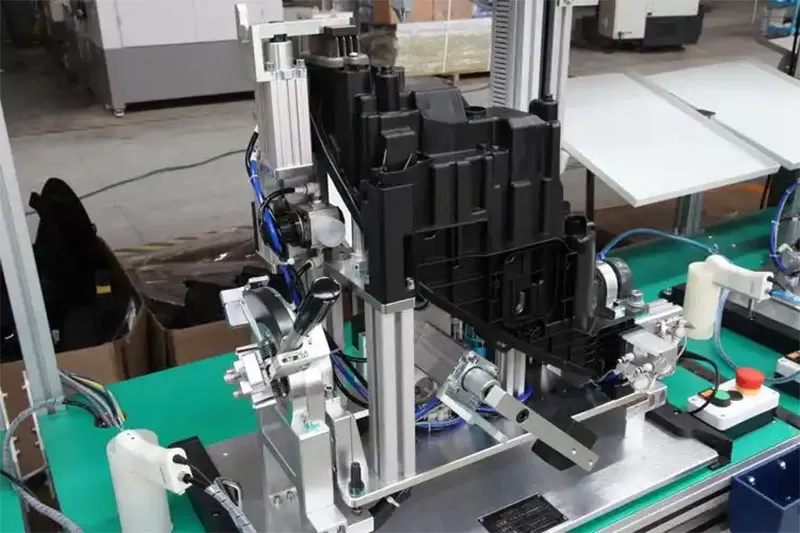

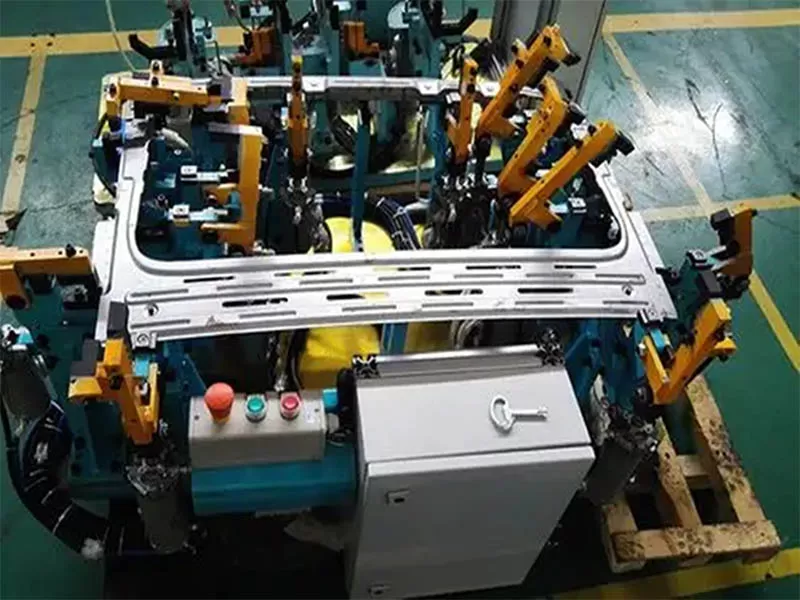

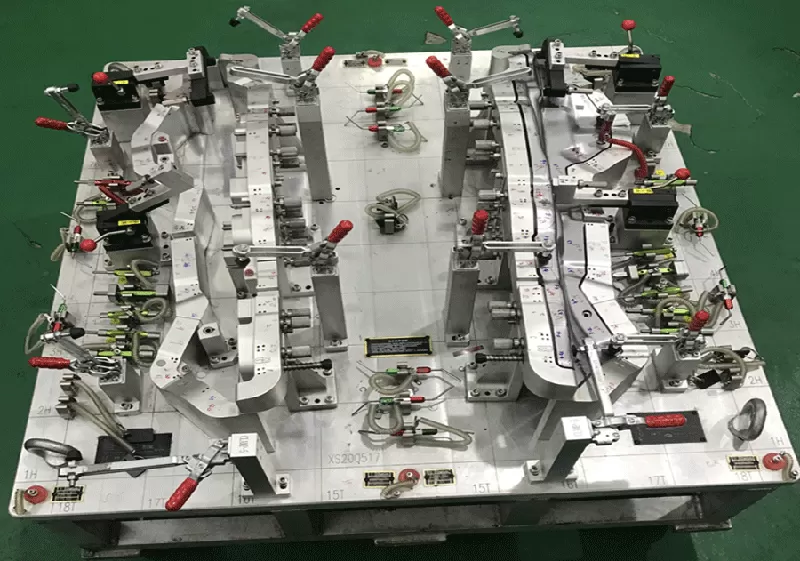

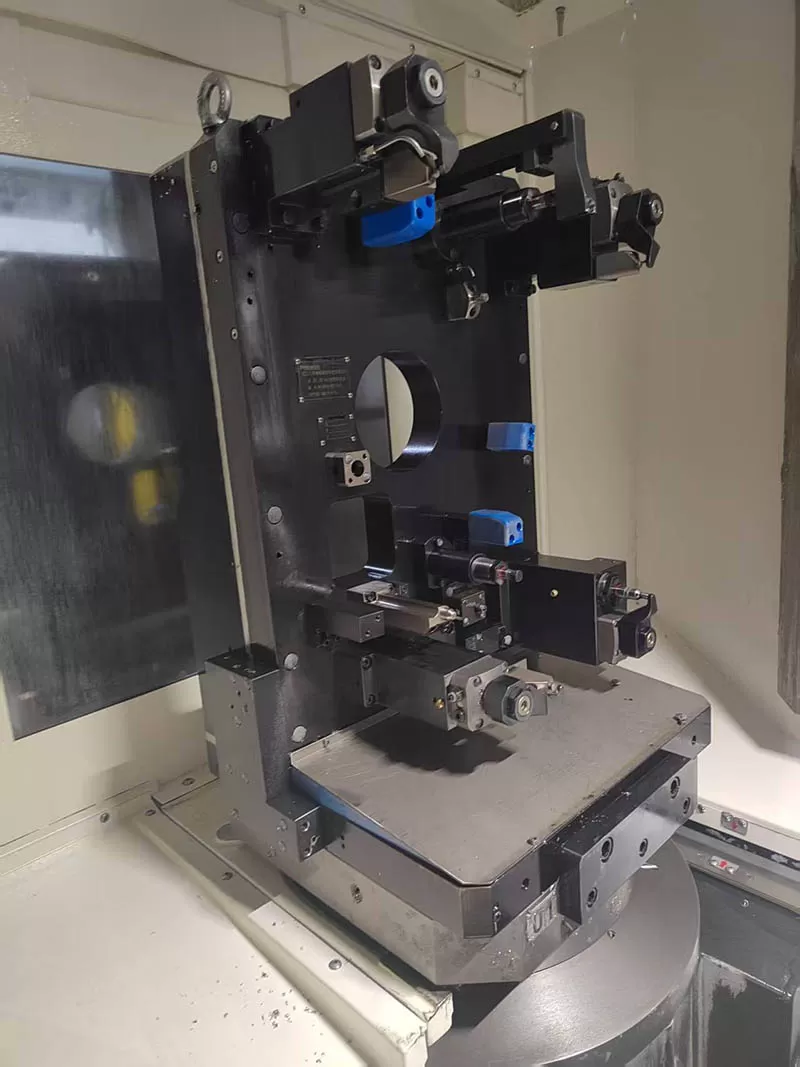

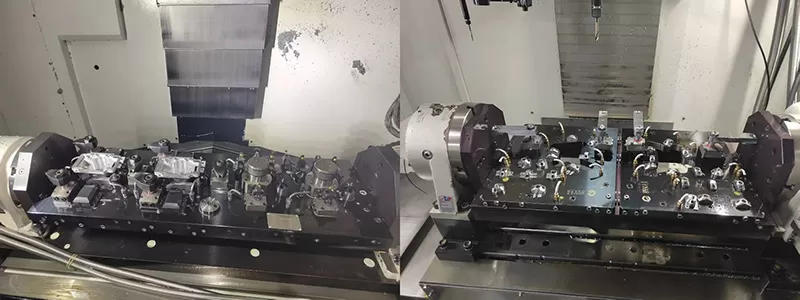

·Production & Machining

We supply carbon fiber machining services with 3-axis and 4-axis milling CNC machines that offer an accuracy up to 0.05 mm. Parts have included tube sleeves for the medical devices, racing parts for bikes, structural components for UAV and battery enclosures for solar energy.

·Quality & Assembly

We are ISO 9001: 2015 certified, which provides internationally accepted standards for quality management. Our sourcing, production, and quality control processes ensure the carbon fiber components free of any defects such as bulging, with smooth edges, sized perfectly to specification and appearance.

Conclusion

The application of carbon fiber in the military, medical, outdoor and industrial engineering industries has greatly promoted the technological progress and product upgrades of these industries. In general, carbon fiber is an ideal engineering material that requires a high strength-to-weight ratio, excellent corrosion and wear resistance, and toughness. At the same time, it is crucial to consider tool and processing variables when processing carbon fiber parts. Hard material coatings are often used to address these characteristics and possible challenges.

At ANOK PRECISION MANUFACTURING (SHENZHEN) Co.,Ltd https://www.anokcnc.com/, we use custom tools in carbon fiber machining. Our engineers simulate tool paths and machining operations to optimize machining parameters such as spindle speeds, feed rates, cutting speeds, etc. So if you need any of these components or prototypes, contact us and get a quote!

Finally, in the process of exploring the complex field of carbon fiber processing, we deeply feel that we still have a long way to go. Solvay, HEXCEL, SGL Carbon, JUNO Composites, Elevated Materials, as the leaders in the industry, their continuous investment in R&D and innovation, meticulous control of process optimization, and accurate insight into market demand have set a very high benchmark for us. We will follow them and move forward towards the goal of becoming an industry leader.

References:

1. https://en.wikipedia.org/wiki/Carbon_fibers

2. https://www.madehow.com/Volume-4/Carbon-Fiber.html

3. https://www.sciencedirect.com/science/article/abs/pii/S1359835X16303451

4. https://iopscience.iop.org/article/10.1088/1757-899X/971/3/032011/meta

5. https://auto.howstuffworks.com/fuel-efficiency/fuel-economy/carbon-fiber-oil-crisis.htm#pt1

6. https://www.proquest.com/docview/222949389/7FAC09C4959E4A6DPQ/1?sourcetype=Magazines

7. https://www.acs.org/education/whatischemistry/landmarks/carbonfibers.html#carbon-fibers-today

8. https://www.researchgate.net/publication/337917403_APPLICATION_OF_CARBON_FIBER_REINFORCED_PLASTICS_IN_AUTOMOTIVE_INDUSTRY_A_REVIEW

9. https://www.prnewswire.com/news-releases/carbon-fibers-strength-to-weight-ratio-revolutionizes-industries-aerospace-automotive-wind-energy-and-more-benefit-from-exceptional-material-301978620.html

10. https://www.researchgate.net/publication/363837398_Analysis_of_The_Number_of_Layers_and_Types_of_Carbon_Fibe r_Against_tensile_Strength_Compressing_Strength_and_Shock_Load_of_Bicycle_frame

EN

EN