Traditional 3-axis machines reach their limits when your parts demand intricate contours or compound angles. Our 4-axis CNC capabilities add rotational precision, allowing simultaneous machining from all angles in a single setup - reducing fixture changes, minimizing errors, and accelerating turnaround for mission-critical components. Whether you're prototyping advanced fluid dynamics parts or producing high-tolerance automotive tooling, the fourth axis transforms how we approach precision. Let's discuss where rotational machining can optimize your next project.

Choose excellent quality machinery to help with your precise machining & manufacturing needs, our engineers have rich experience working in the precision engineering industry. Full range of projects from small to large. Tight tolerance down to +/- 0.002mm. ISO9001:2015 Certified.

Short lead time and proof of certifications & inspection reports with every order. We mind our customers' after-sale service. Our optimized 4 axis CNC machining processes and streamlined logistics ensure faster turnaround than standard suppliers, reducing downtime for your production.

Excellent customer service with clear communications, instant online quote within 24-48 hours. Our 4 axis machining specialists review your RFQ personally to optimize manufacturability and cost-efficiency before quoting.

Cost-competitive in raw material considerations in a tough marketplace. From aerospace-grade aluminum 6061/7075, stainless steel 303/316, to engineering thermoplastics like PEEK & Delrin, we support prototyping to high-volume production with certified raw materials. We assist you with the most attractive cheap 4 axis CNC prices.

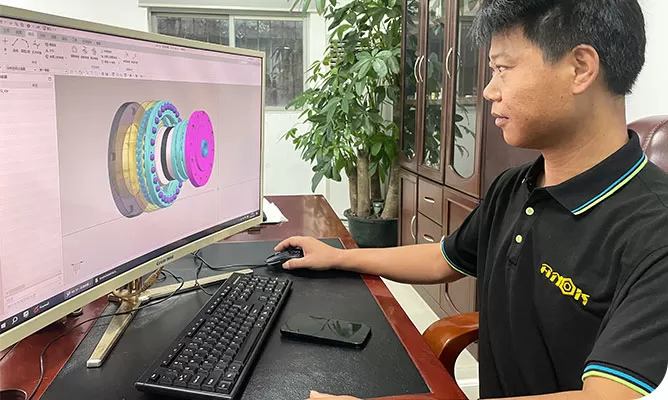

The process begins with the creation of a Computer-Aided Design (CAD) model of the part that needs to be machined. This is one of the most crucial parts of the four-axis CNC machining process. We apply the latest mold design software and CAD software tools, such as AutoCAD, SolidWorks, CATIA, Pro-E, and UG, to ensure precision in the CNC machining design and mold development.

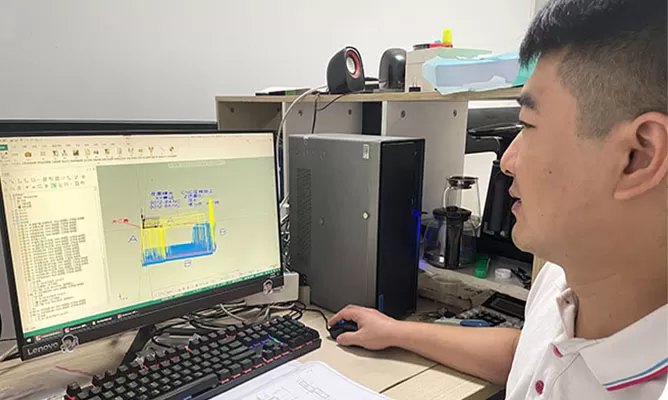

In this step, the design is translated into CNC-compatible codes that are readable by the CNC machine. The tool path needs to be programmed according to the shape and size of the workpiece, ensuring compatibility with the four-axis CNC machining setup. The cutting path and cutting depth are determined through CAD software and CAM software, which helps optimize the machining process for precision and efficiency.

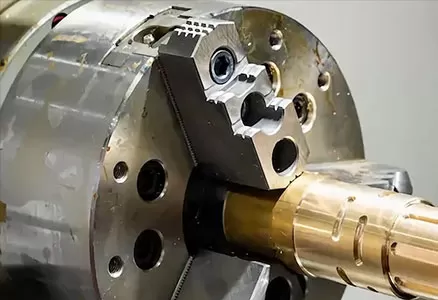

The machine needs to be set up for the specific job in the CNC machining process. The workpiece is mounted on the CNC machine, and the machine is configured with the appropriate cutting tools for the task. During this setup, precise adjustments are made to ensure proper alignment and to optimize the cutting path for 4th axis CNC milling or other advanced CNC operations.

The machine then begins the machining process. It moves in the X, Y, and Z directions while the mounted workpiece rotates on the A axis, allowing continuous machining at different angles. Once the machining process is completed, the machinist needs to clean the machine and tools and take them to the right position.

We have the 4-axis CNC machining capabilities to produce small, medium, and large complex components in a wide range of material grades, such as aluminum, stainless steel, copper, steel, and plastics. Our advanced CNC milling process ensures precision when working with both metal and plastic materials, making it ideal for custom machining projects. Get in touch with us for more information about the materials available for 4-axis machining and how we can meet your specific requirements with our machining expertise.

4 axis machining has a wide range of applications due to their ability to create complex parts and components.

Here are some industry sectors we are served:

Our experience and expertise in machining business give us a lot of confidence in our 4 axis CNC machining service. ANOK owed 8 sets of 4 axis CNC machines in house to support your projects, we have the capability to make your prototypes and productions on time delivery and good quality. From medical parts to automation components, we are now working with companies all over the world.

4-axis machining can work with a wide range of materials, including metals (like aluminum, steel, titanium), plastics, and composites. The choice of material depends on the application, desired properties of the final product, and the capabilities of the specific 4-axis CNC machine.

4-axis machining is used to create complex parts that require machining on multiple sides or involve intricate features. Common examples include aerospace components, medical devices, automotive parts, impellers, gears, and custom molds. It is also commonly used for prototyping and custom machining projects.

The choice between 4-axis and 5-axis CNC machining depends on the complexity of the part and the specific requirements of the project. 4-axis machining is suitable for parts that require machining on multiple sides but do not need the full flexibility of a 5-axis machine. If your part requires extremely complex geometries or intricate features that need to be machined from almost any angle, 5-axis machining may be a better option.

While 4-axis machining is highly versatile, it does have limitations. These include limited access to certain angles that might be reachable with 5-axis machining, and potential challenges in programming more complex tool paths. Additionally, the setup and fixturing can be more complex than with 3-axis machines.

Programming a 4-axis CNC machine typically involves using CAD/CAM software to design the part and generate the tool paths. The software allows you to define the movements of the X, Y, Z, and A axes. This can be more complex than programming for a 3-axis machine, requiring careful consideration of the rotation axis and how it interacts with the other movements.